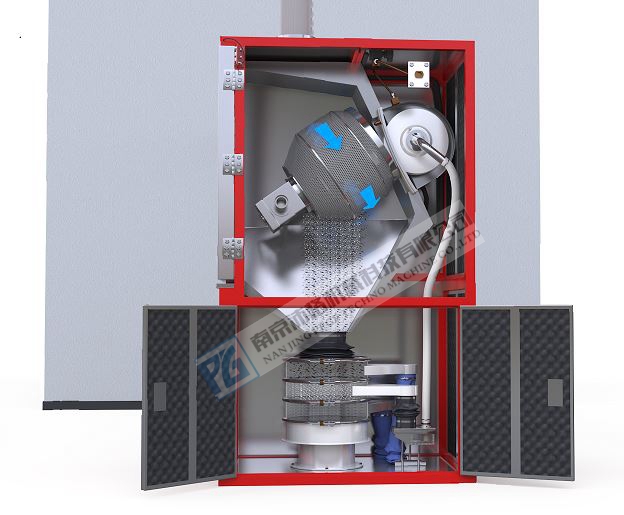

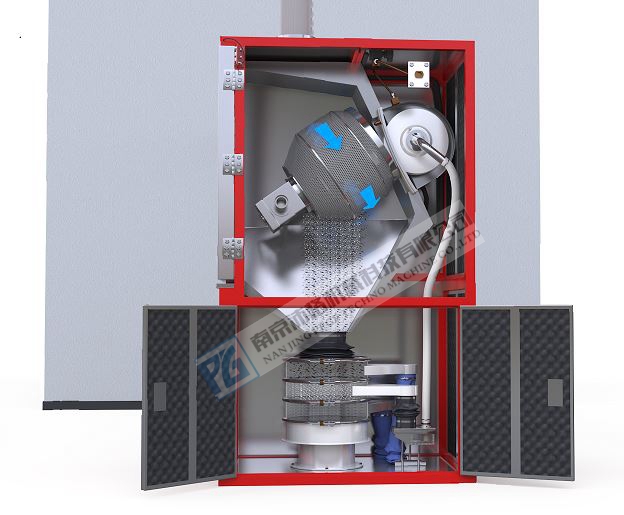

The machine typically consists of a chamber and a tumbling barrel where the parts are placed.

Here's a general overview of how a cryogenic deflashing machine works:

- Load the parts: The parts to be deflashed are loaded into tumbling barrel. These parts may be made of rubber, plastic, or similar materials and may contain excess flash or burrs that need to be removed.

- Cool down the chamber: The chamber is cooled to cryogenic temperatures using liquid nitrogen or another cryogenic cooling medium. Liquid nitrogen is commonly used due to its low temperature of around -196 degrees Celsius (-320 degrees Fahrenheit).

- Freeze the parts: Once the chamber reaches the desired temperature, the liquid nitrogen is sprayed into the chamber or poured over the parts, rapidly freezing them. The extreme cold makes the undesired material brittle and easier to remove.

- Blasting action: There is a blasting wheel at the back of the machine, it is set in motion, causing the frozen parts to be blasted. While the barrel tumbling helps all the parts can be blasted evenly, this process is to remove the excess flash or burrs from the parts by inducing collisions between the parts and thus breaking off the brittle material.

- Thawing: After the desired tumbling duration, the liquid nitrogen supply is stopped, and the parts are allowed to warm up. Thawing takes place at ambient temperature, causing the frozen excess material to become less brittle.

- Separation: Once the parts have been deflashed, the media and flashes will be separated by high efficient stainless steel made vibrator.

- Inspection and finishing: The deflashed parts are typically inspected for quality control purposes. If necessary, additional finishing processes such as washing, drying, or polishing may be performed to achieve the desired final result.

Cryogenic deflashing machine from Nanjing Pege Techno Machine Co., Ltd provides an efficient and non-abrasive method of removing excess flash or burrs from parts, minimizing the need for manual labor and reducing the risk of damaging the parts during the deflashing proces

English

English français

français español

español

IPv6 network supported

IPv6 network supported