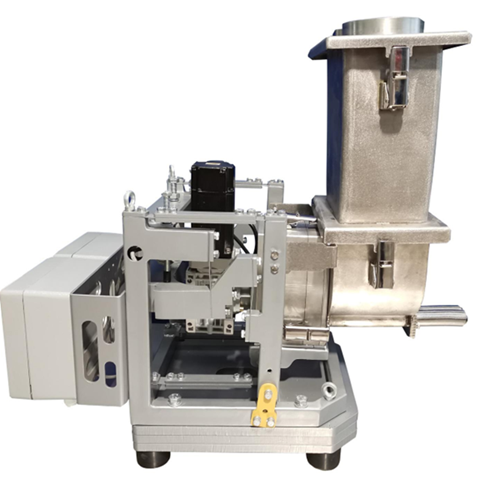

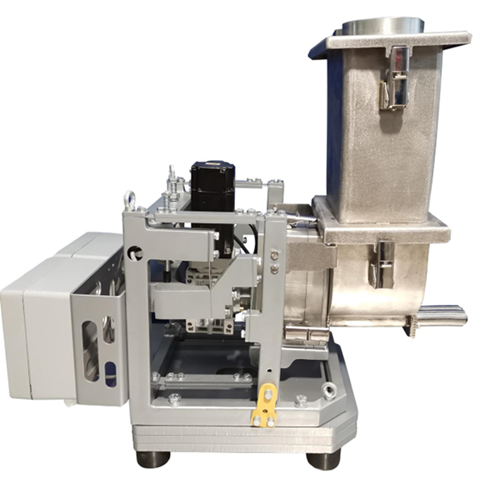

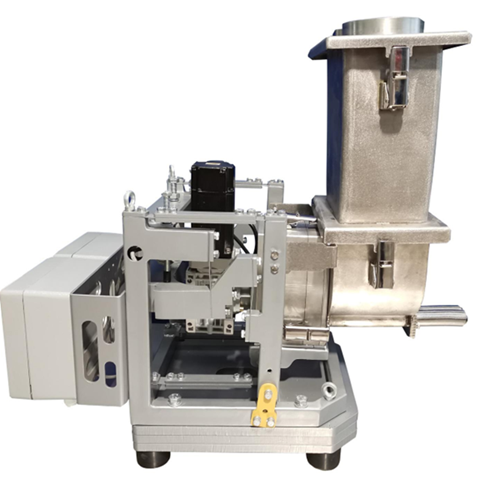

Twin Screw loss-in-weight Feeder

Company Profile

Nanjing Pege Techno Machine Co., Ltd has been working with bulk ingredients feeding, weighing for more than 10 years. We have gained knowledge and have become a reliable feeder supplier for various customers.

Whether for use in the plastics, chemical, pharmaceutical, food, pet food, detergent, ceramics, glass or construction material industries – the customer and his requirements are most important. Before we submit a quotation, we analyze your ingredient and work with you to determine your needs. Continuing this with our 10 years of experience we select the best device from our extensive product line which can feed any conceivable ingredient. All our machines can be further modified to fit the individual needs of our customers.

Besides extensive process advice we have many services such as feeding trials in our test labs, start-ups and operator training on site or at our training center.

We also offer maintenance, customized screws, spare parts and repairs as parts of our comprehensive after-sales services at reasonable prices.

Loss in Weight Feeding Systerm Principle

In loss-in-weight feeding, the entire feeder, hopper and material are continuously weighed. As the feeder discharges material, the rate of decline in system weight is computed, and feeder speed is adjusted to maintain the desired (set) rate.

Gravimetric Feeding Machine Application Material

Resin Granules, Resin Powder, Calcium carbonate, French Chalk, Tio2, Carbon Black, Samll Flow Range Request

Applications on the Industries

The key function of loss-weight-feeder is to realize continuous and precise batching and dosing.

Plastics industry.

Processing of plastic, films, coatings.

Chemical industry.

Premixes for extrusion, detergents, pesticides, fertilizers, building materials.

Food Industry.

Cereals, muesli bars, sugar mixtures, milk powder, diet breakfast drinks, salt iodization, fluoridation, aromatization.

Pharmaceutical industry.

Production of vitamins and active ingredients.

Environment.

Flue gas cleaning, water processing, diesel particle filters.

Twin Screw Weighing Feeder Features

★The cantilever sling type weighing frame supports the storage hopper, which has the characteristics of vibration reduction and anti-level interference, which can effectively shield the non-weight value interference from the vibrator, and measure the flow of the system more accurately

★Use double motor to control feeding and stirring, the stirring speed is adjustable to ensure a most suitable gear ratio with feeding speed.

★The features of optional servo motor like light weight, small volume, low vibration, stable torque in low speed will improve the feeder the ability of anti-interference and feeding.

★Detachable structure, simple maintenance and cleaning.

★Vertical U shape hopper with mirror-like inner wall and without corner enclosure can ensure no bridge of the materials.

★No stirring motor on the top of hopper ensure stable frame, less interference and precision weighing data.

Sucessful Cases of Pege's Weighing Dosing&Batching System

With many years of expertise and continious development, the gravimetric feeding machines had been accepted by many customers and are applied in many industries.

Pege will keep providing qualified loss in weight weighing feeder for customers both in China and Abroad.

FAQs of Loss in weight Feeder

1. How does weighing feeder work?

Gravimetric loss in weight feeder is an instrument that is important to control and measure the speed of a substance in an instrument system. This equipment can handle the bulk solids. It allows the solid to discharge at a constant weight per unit time. The unit of measurement is kg/min or Kg/hour. The signal about the weight is used as a system of feedback control. It controls and monitors the feed rate that enters a instrument. The weighing systems include several examples such as platform scales, load-cells, weigh hoppers, etc. Depending on the overall process, the gravimetric feeder may be a loss-in-weight system or a gain-in-weight system.

2. What are the most important benefits the gravimetric feeder can give to you?

To ensure excellent quality of final product by accurately metering the bulk ingredients.

To reduce the labor cost and improve labor work environment

To Improve product stability

Reduce dust pollution and be more environmentally friendly

3. What is general accuracy rate of the good loss in weight feeder?

Our general feeder’s feeding accuracy rate can be 0.5%. The micro twin screw loss in weight feeder accuracy rate can be up to 0.3%.

4. What is the main composition of a typical loss in weight feeder?

Loss-in weight feeders for bulk materials consist of storage hopper, controlled feeding devices such as augers, screws chutes, pumps as well as scales or load cells, loss-in-weight controllers or rather loss-in-weight feeder controllers. Optional: e.g. agitators to improve the quality of the bulk material.

English

English français

français español

español

IPv6 network supported

IPv6 network supported